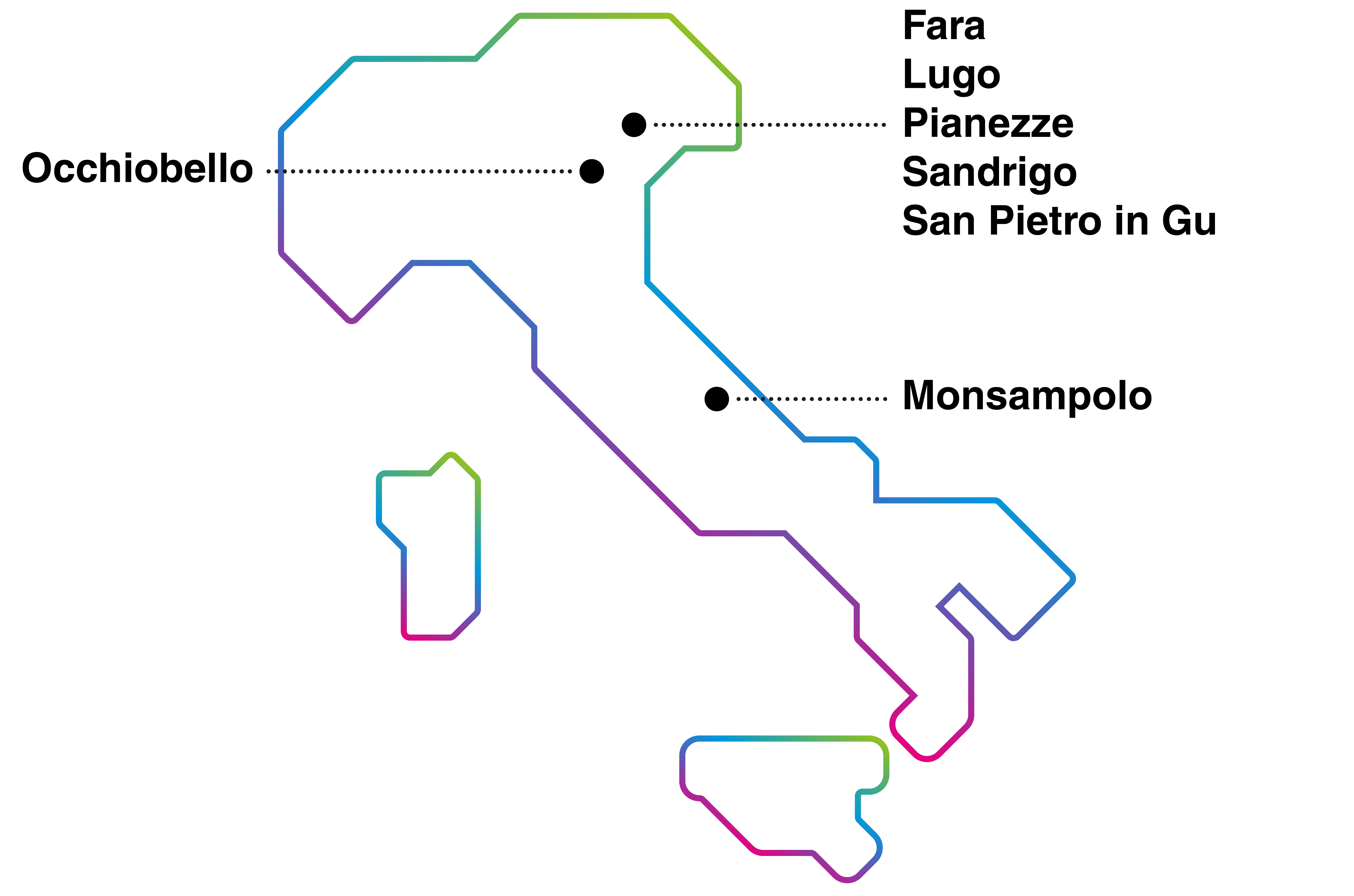

FITT manufactures hoses, pipes and systems for gardening, public and private construction, industrial plants, and infrastructures. With headquarters in Sandrigo (VI), FITT has 870 employees, 9 production sites and 2 logistics hubs.

The Innovation & Technology department of the headquarters is dedicated to the research of materials and innovative solutions both for the development of products that ensure better performance and lower environmental impact, and for the conception and design of new processes and technologies that can guarantee the highest quality standards available on the market today in terms of efficiency, functionality and reliability.

A “Concept Lab” – a production department digitally integrated with the design department and entirely dedicated to the development of new products and process technologies – supports its innovation capabilities, in line with the principle of “open innovation“, one of FITT core concepts.

This approach translates into the building of solid and continuous partnerships with the academic world and the main Italian universities (University of Padua and Milan Polytechnic), with the main international suppliers of polymers (Basf, Vinnolit, Chemone) and with important product innovation studios (Momodesign, Galileo Visionary District).

Fully automated logistics centre thanks to the integration between the SAP platform and the Toyota software that coordinates the wire-driven trolleys.

Data is acquired through the Wi-Fi network, taking advantage the most advanced RFID technology known as Ultra High Frequency (UHF), with zero error margin.

- A surface of 80,000 square metres, 27,000 of which covered

- 15 unloading ramps

- 60,000 pallets of storage capacity

- Automated warehouse dedicated to E-commerce: 12 metres high, 2 racks, 150 storage trays, 3 bays on two levels, one of which dedicated to autonomous courier pick-up

- Daily picking with 24/48-hour delivery throughout Italy

Business Solution

FITT exists to improve the business of its customers, by providing complete thermoplastic pipes, hoses and systems for the transport of liquid, gaseous and solid substances, with products at the forefront of technology, design and sustainability.

FITT develops solutions that ensure safety, performance and ease of use, applicable to 9 dedicated and specialised business units.

Contact FITT