Gafa 2023 has come to an end. The event saw FITT consolidate its responsibility journey, announced to the public during the 2019 edition of Gafa and restated in 2022 with the launch of its sustainability strategy, The Responsible Flow. Together with innovation, which has always been the driving force behind FITT’s business, leading to the […]

The plastic value chain in Europe and in FITT: from waste recycling to the circular economy

The first real plastic material was invented in the mid-19th century. Since then, thanks to their unlimited innovative potential, plastics have not stopped evolving, offering sustainable solutions to our rapidly changing needs.

As we saw in the last article (link to second article), the plastic sector includes efficient materials that allow us to have clean water, sewage systems, safe food, energy-efficient homes, green transports, renewable energy, healthcare and much more.

Plastics will therefore continue to shape our present and our future. But only when we will be able to overcome the global challenges related to the negative impact caused by their dispersion in the environment, will we be able to exploit the full potential of these materials.

This is why it is necessary to create a plastic value chain, starting with the proper recycling of waste and leading to the circular economy, and which can continue to provide benefits to society, whilst at the same time having a positive impact on the environment.

Recycling of plastic waste in Europe

Nowadays, 60% of plastic products and components have a period of use that goes from 1 to 50 years or more.

This time frame determines when they will potentially become waste.

This is why the amount of plastic waste collected in one year does not match the production or consumption quantities for the same period.

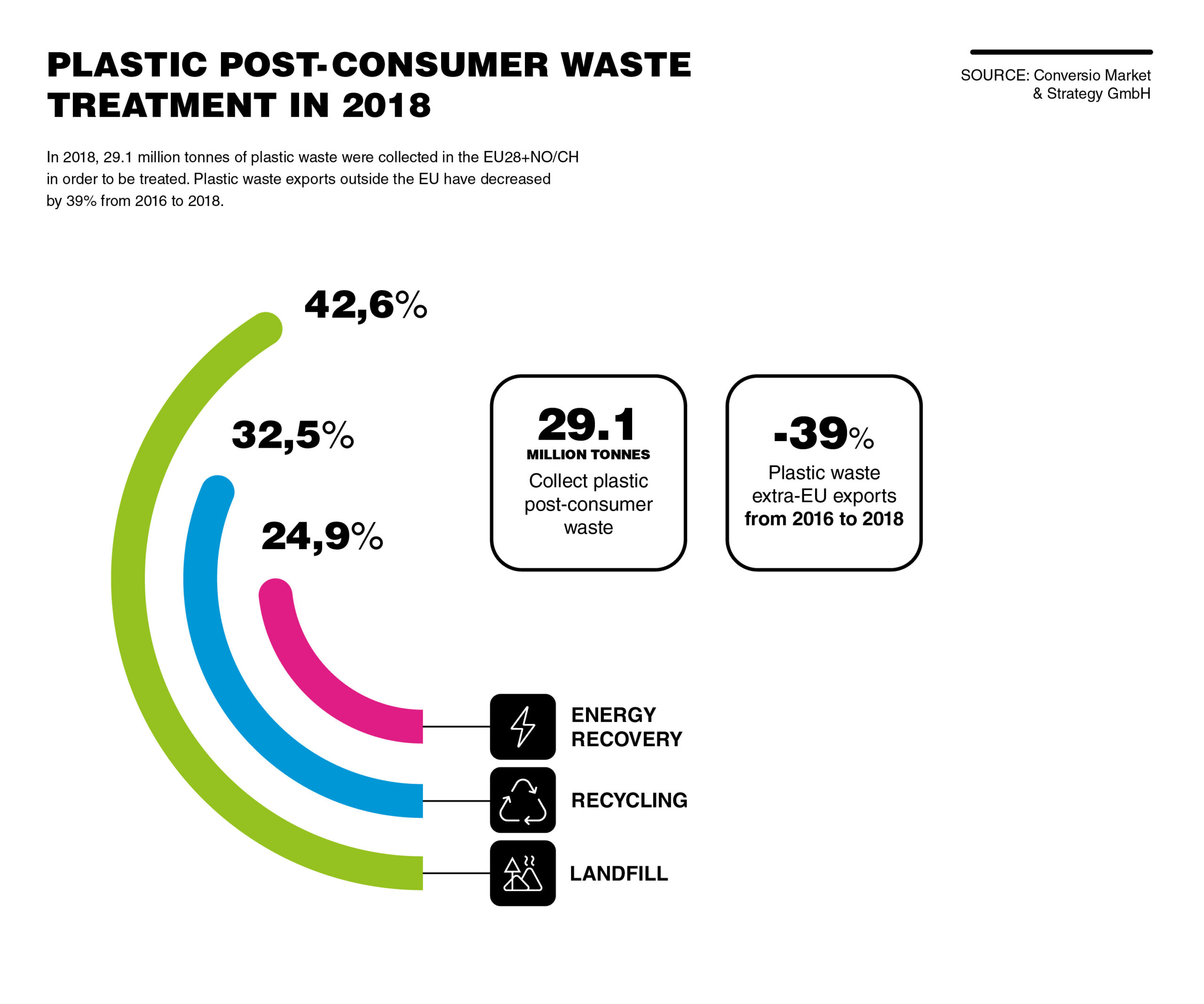

29.1 million tonnes of plastic waste were collected in Europe in 2018. Of this quantity, 32.5% was recycled, 42.6% went to incineration plants, and 24.9% went to landfill.

Fig. 1 The treatment of plastic waste in Europe

Source: Conversio Market & Strategy GmbH

From 2006 to 2018, the amount of plastic going to landfill decreased by 44%, while the amount going to incinerators increased by 77%, and the amount recycled increased by 100%.

Europe has decided to pursue the target of zero waste to landfill for recyclable materials such as plastic by 2030. This will lead EU countries to further develop and increase their support for the circular economy.

Recycling plastic waste at FITT

The link between FITT and plastic waste recycling follows three different paths.

- Firstly, each year FITT recovers around 3,000 tonnes of PVC waste from its own production through grinders and micronisation processes within the plants. Waste therefore becomes a new resource that is put back into the production cycle, capable of generating further value.

- Secondly, every year FITT uses around 5,000 tonnes of regenerated PVC granules obtained from waste from other markets, such as the automotive and the construction sectors.

- Lastly, in its new product development strategy, FITT has decided to favour materials for which active post-consumer waste supply chains already exist, such as polypropylene.